CONTACT US 24/7 WHEN YOU NEED OUR SERVICES...

Crathes Culvert Pipe Lining – Before

Crathes Culvert Pipe Lining – After

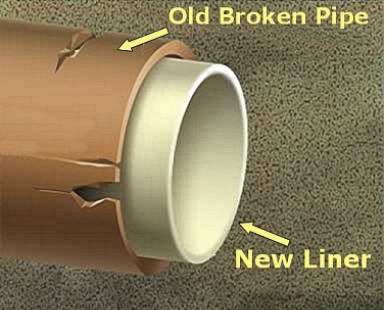

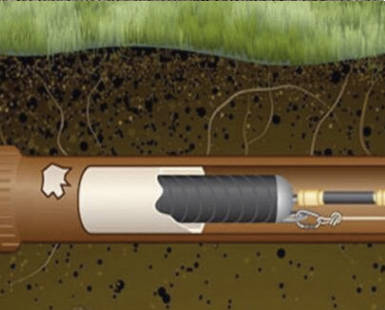

Patch Lining & Pipeline Rehabilitation is the most efficient and cost-effective process to use when repairing pipes, under- or above ground. All pipe types, such as sewer, surface or effluent, can be repaired to return them to full operational integrity. In short, Pipe Lining is when a resin-soaked GRP ‘sock’ is put into the damaged section of pipe and inflated and left to cure. The ‘sock’ adheres to the original pipe surface to create a new pipe within the old pipe and restores the structural strength to the old pipe.

As it is a ‘no-dig’ process, it ensures minimal disruption to your site or the public areas that a pipe may cross. There are no open excavations to be made safe, no risk of unknown utility strikes, less hazards, no permits and traffic management required. This system allows you to get to work quickly and repair the pipe to prevent further damage from occurring, stop pollution to local watercourses or re-start a critical industrial process.

Recent lining projects include work within hydro power stations, open water culverts, and public and private sewers. All types of pipe material, e.g. clay, plastic, cast iron, brick, concrete, etc. can be re-lined to return the pipe to full operational condition and flows.

Pipe Lining and Patch Lining repairs can be carried out in pipe diameters from 100mm to 1.5m and will provide up to 50 years security on the repair.

For more information on how we can help repair your pipe, please call 01355 268 282 and we will provide further details to you.